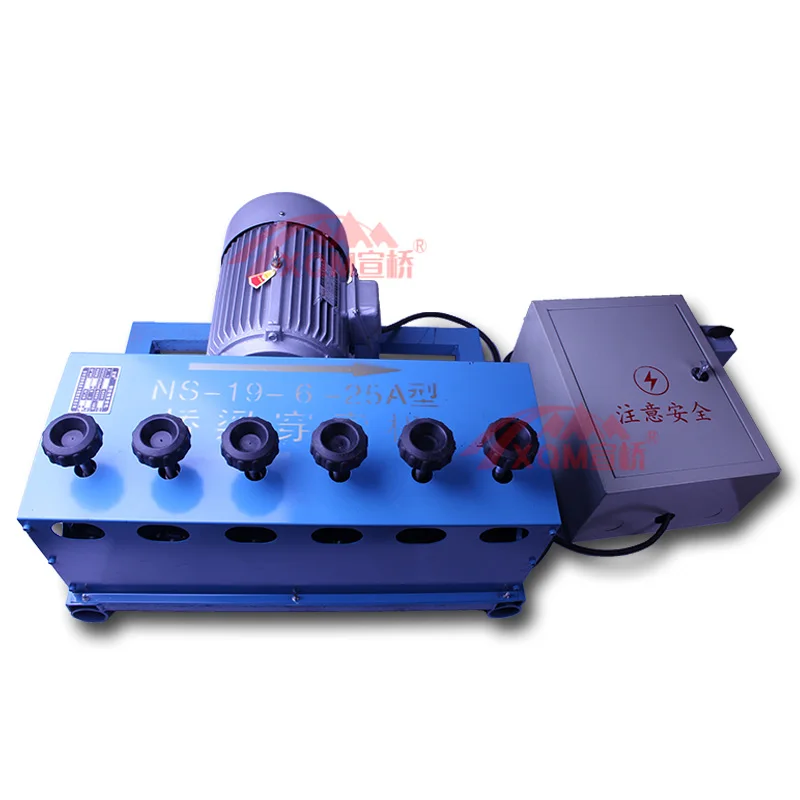

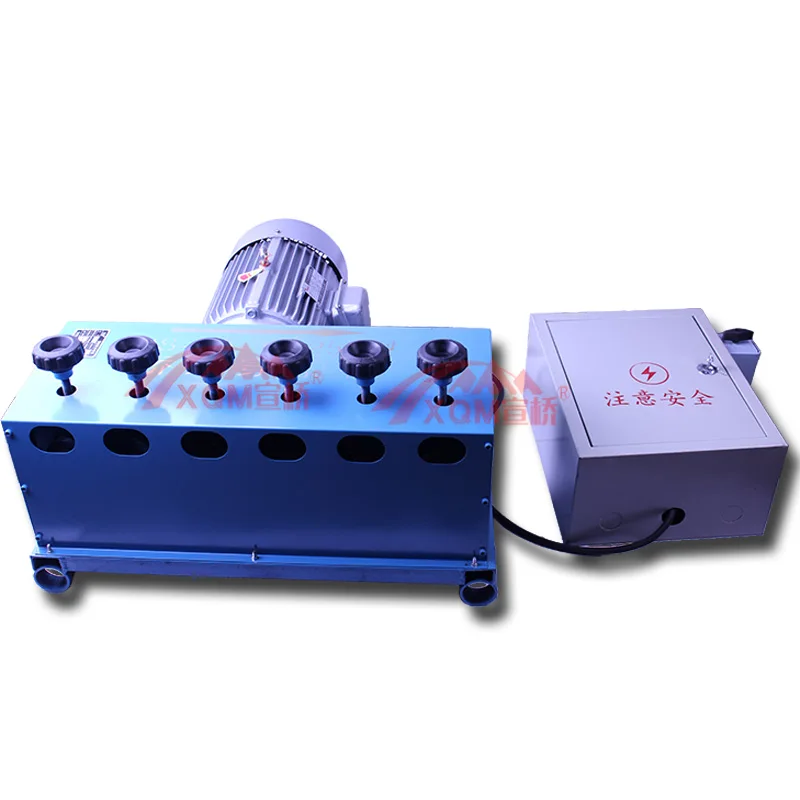

Prestressing Concrete Construction PC Strand Pulling Equipment Strand Pusher Machine for Post Tension

Detailed Description

Technical performance parameters and characteristics of CS series strand pushers:

1. CS15-3’s maximum pushing length can be up to 140 meters (curve) / CS15-4’s maximum pushing length can be up to 200 meters (curve); both are suitable for all bridge components of domestic express way high-speed rail high-rise projects of (cast-in-place prefabricated suspended scaffolding cable-stayed boom, etc.), ensuring successful reeving. Failed machine can be returned.

2. Transmission is realized by high-strength anti-wear large diameter pressure roller system with patented design of double pushing channels (The life span of the accessories is three times longer than that of similar products, and it will not affect the construction period during the construction). The design of the new whole machine gear power transmission is adopted (The torque is 2 times bigger than the belt conveyors in the market). And a variety of bullets provided by the manufacturer offer an effective solution to the challenge of long-spanmulti-curved bridges.

3. The pushing speed can be fast or slow (1-80m/min) with computer frequency conversion electric control system. With leading technology, low-speed large torque, or high-speed high-pass can be realized, which is flexible and convenient, accurate and reliable (multi-function dual-control smart electric control system is available for additional charge).

4. Designed for complete construction environment, the operation is simple and convenient for everyone, adapting to the actual situation of mixed quality of the construction workers. Two people are needed for operation only. The average daily pushing volume is 40 tons -50 tons strands. The fast speed and high efficiency will save substantial time and cost for the project.

5. Operating voltage: 380V; motor power: CS15-3 4KW; CS15-4 5.5KW, 7.5KW or 11KW.

6. Absolutely solid and reliable materials are used; accessories are twice larger and thicker than domestic similar products to ensure the durability.

7. A brand name of prestressed equipment from Liuzhou with 10 years of professional manufacturing experience and advanced technology is trustworthy. The strand pusher (pushing means to push the prestressed strand through the hole) adopts mechanical transmission and roller clamping. Forwarding, retreating, continuous transmission or jogging can all be realized. With stepless transmission speed regulation, easy operation, reliable performance, and significant efficiency, the machine greatly reduces the labor intensity, and therefore is widely used for construction of large bridges, box girders and structures as an ideal strand pushing machine.

Technical parameters

Technical performances and the differences between the two are as follows:

1. The effective maximum pushing length can be up to 200 meters (curve), suitable for all bridge components of domestic express way high-speed rail high-rise projects of (cast-in-place prefabricated suspended scaffolding cable-stayed boom, etc.).

2. Both use six groups of high-strength anti-wear large diameter pressure roller system for transmission and patented design of double pushing channels. The life span of the accessories is three times longer than that of similar products. On the prefabrication site, two strands can be pushed simultaneously. And a variety of bullets provided by the manufacturer offer an effective solution to the challenge of long-spanmulti-curved bridges.

3. CS15-3 uses uniform speed (50m / min), while CS15-4 can be fast or slow (1-80m/min) with computer frequency conversion electric control system. Low-speed large torque or high-speed high-pass can be realized, which is flexible and convenient.

4. Designed for complete construction environment, the machine is light and flexible. Two people are needed for operation only. The average daily pushing volume is 40 tons -50 tons strands. The fast speed and high efficiency will save substantial time and cost for the project.

5. Operating voltage: 380V; motor power: 3-11KW (optional)

Reviews

There are no reviews yet.